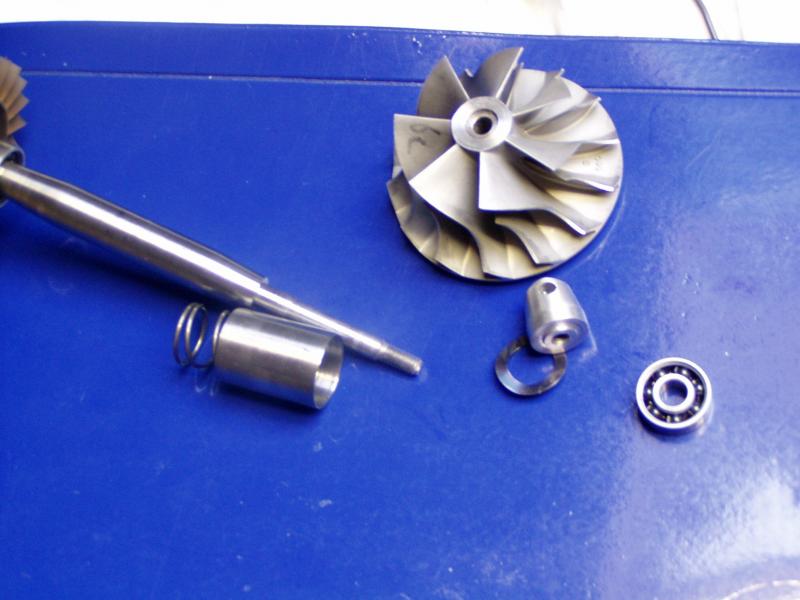

I noted too much gap between compressor blade and intake cover...

I think so too. Specially looking at the second segment of the curve. This is not very difficult to resolve. Try to put it straight into the lath and align it as good as possible. Than make pen stripes and scrape the compressor in. At the point where the compressor blades touches the casing very gently turn/machine it away and then try again....and again...and again. After about 1-2 hours you will have a perfect fit. Now you need to make a ring/shim to extend the casing forward again as this alignment is too close now. Did this operation several times on my old KJ66's, also after a front bearing failure which damaged the casing.

Best regards,

Gerald